Fontaine® manufactures 3 different types of backing screens: Double bridge backing screens, wire mesh backing screens and punched backing screens. All of them can be customized independent from any centrifugal manufacturer, and available in any dimensions.

Backing screens

Contacts

Manuel Martin

Managing Director

Phone: +49-241-91863-10

Fax: +49-241-91863-60

Mobile: +49-176-19186312

Details

Double bridge backing screens

Our stainless steel double bridge backing screens are, independent from any centrifugal manufacturer, customized, and available in any dimensions. Its solid design and material thickness lead to a long operating life. In addition to the large open area, optimal supporting points allow a high molasses drainage. We supply the double-bridge backing screens pre-bend to the basket radius, ready to be installed.

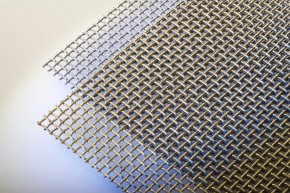

Wire mesh backing screens

Fontaine® wire mesh backing screens are available in stainless steel and brass. We provide wire mesh customized, independent from the centrifugal manufacturer, in any dimensions, wire diameter and mesh sizes the customer requires. In addition to the classic wire mesh version, a “DOVEX version” (one site flat) is also available in both materials. The wire mesh backing screens can be supplied cut-to-size or in rolls.

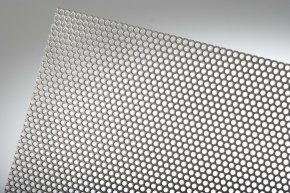

Punched backing screens

Fontaine® punched backing screens are available in stainless steel and copper, and independent from the centrifugal manufacturer, customized in any dimension. The punched backing screens can be supplied cut-to-size or in rolls. Short delivery times are guaranteed due to delivery ex stock.

| Double bridge | Mesh wire | Punched | |

|---|---|---|---|

| max. width in mm | 1330 | 1200 | |

| Open Area in % | 58 | 25-83 | 23 |

| Total thickness of the screen in mm | 6,0 | 2,5 | |

| Material thickness in mm | 1 | 0,5 | |

| Mesh pro inch | 1-500 | ||

| Wire diameter in mm | 0,025-3 | ||

| Meshes per cm | 0-200 |